This is part two of a two-part series. To read part one, please click here.

Navigating Pitfalls to Build a Better Supply Chain

Once you’ve been around awhile, you notice that successful change requires a robust integrated set of components that overcome all obstacles and overwhelm all resistance and resistors. Success hinges on the fact that no required component is missing.

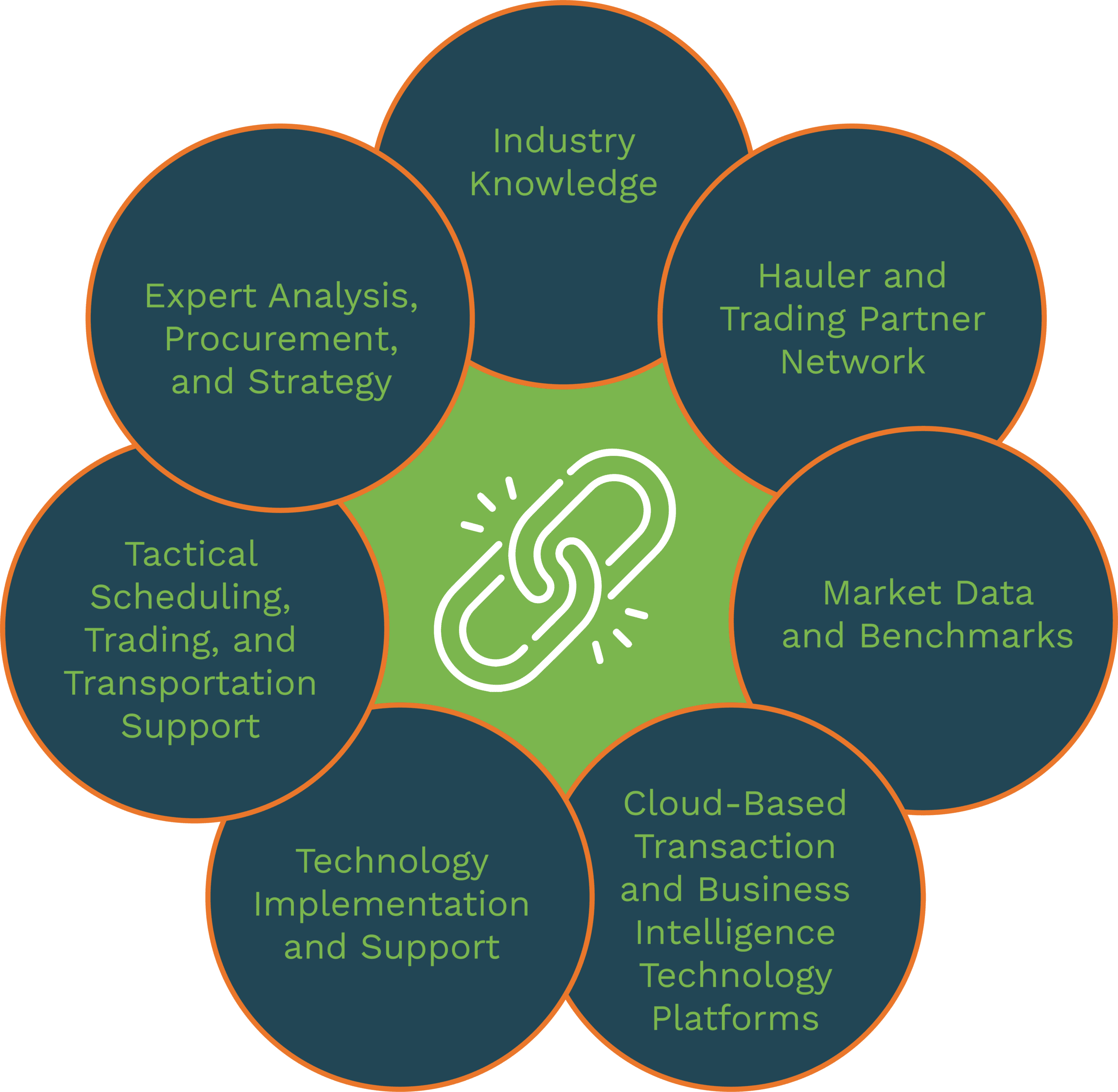

So, what does a comprehensive set of supply chain components look like? Here’s a fairly comprehensive framework.

Individually, all these components make sense.

- Industry knowledge ensures understanding of critical priorities, avoidance of pitfalls, and avoidance of on-the-job learning time

- A network of haulers and trading partners is key in dairy, where success means finding the best source or home for perishable product and the lowest cost reliable hauler to move it

- Every supply chain manager needs benchmarking and market data to assess their progress; where they have opportunities to improve, and how much improvement they have made

- Cloud-based transaction and BI platforms that evolve and improve with time, connect supply chain networks, and provide the data to drive better decisions about where to move product, on what hauler, and at the best rate

- Technology implementation and support capabilities are critical for you and your users to have visibility to activity, assess conditions, and make and execute key decisions

- There is no one better at getting the most out of a technology platform than the developer and owner—so a capable scheduling, trading, and transportation service team using the platform is a tremendous asset

- Finally, expert analysts and supply chain strategists are needed to dive into the sea of data, process it with powerful modeling, simulation, and optimization tools, develop compelling insights and recommendations, and make and execute plans to improve supply chain performance

But do you need to find solutions that include all of these capabilities in a fully integrated package?

Yes, and here’s why – increasingly, the core challenge is making the pieces work together. There are so many costs and complexities of integrating technology platforms and linking processes – including the finger-pointing and blame games between different providers – that it is better to have fewer providers and components to integrate!

With integrated, comprehensive providers, you get a faster path to improvement with fewer impediments. Said another way, even in the perfect theoretical world, you need at least two systems—an ERP to connect and manage your company internally, plus an external platform that connects you to your contract and spot trading partners and haulers. Since each disparate component of the supply chain adds exponentially to the challenge of getting everything and everyone to work together, the fewest possible multidimensional solutions are needed to minimize complexity, cost, and risk.

Finding Fully Integrated Solutions

Dairy.com offers, by far, the most comprehensive suite of dairy-specific technologies and services. We have been developing, acquiring, and integrating the best-of-breed pieces in supply chain technology, consulting, managed services, market/benchmark data, and implementation resources.

When you consider the breadth and depth of the key capabilities, including: